You know that sick feeling when a customer wants to buy your hottest product and you’re sold out? Or worse when you’ve got $10,000 worth of stuff nobody’s buying sitting in your warehouse? Yeah, inventory problems keep business owners up at night. A proper stock control system solves exactly these issues.

Here’s the thing: implementing a solid stock control system fixes both problems at once. Consequently, you’ll keep products in stock when customers want them while avoiding the cash drain of excess inventory. Let’s dig into how this actually works.

Understanding Stock Control Systems

What Stock Control Really Means

A stock control system is basically how you track what you’ve got, what you need, and when to order more. That’s it. Nothing fancy.

The goal? Simple. Keep enough inventory to fill orders without drowning in unsold products. Therefore, your cash flow depends on getting this right.

Why This Matters for Your Bottom Line

Bad inventory management hurts in multiple ways. First, running out of popular items loses sales right now. However, it also sends customers to competitors who might steal them forever. On the flip side, buying too much locks up cash you could use for marketing or new products.

According to Shopify’s inventory research, businesses with good stock control cut carrying costs by 25-30%. Moreover, they fill orders faster. That’s real money staying in your pocket instead of sitting on shelves.

What Makes Systems Actually Work

Every good stock control system has a few key parts. First, you need accurate tracking showing what’s in stock right now. Second, automatic alerts tell you when to reorder. Third, you need some way to predict what customers will want next month.

Additionally, modern systems connect to your store and update inventory as orders come in. Consequently, you won’t accidentally sell stuff you don’t have. That’s embarrassing and expensive.

Types of Stock Control Systems

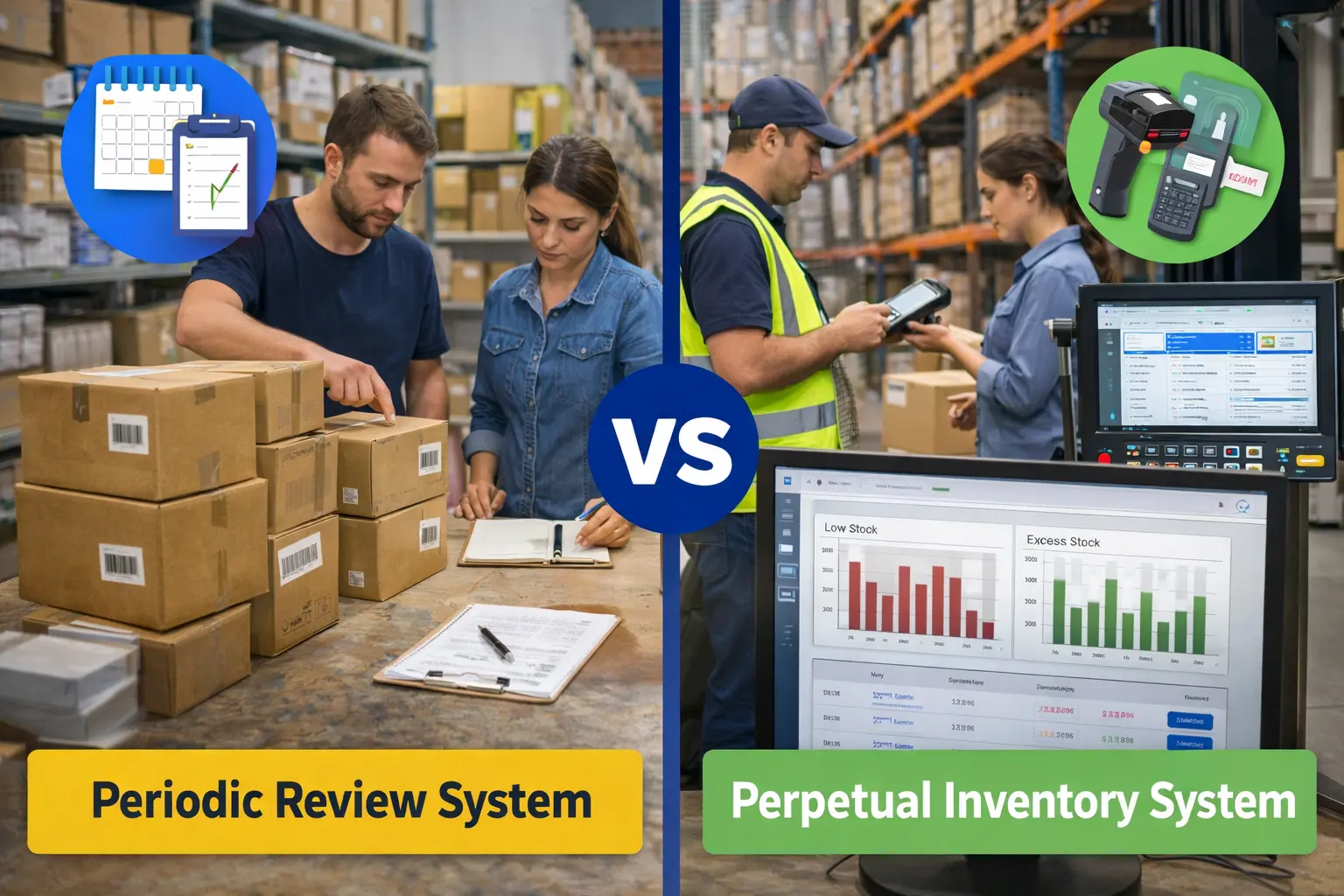

Periodic Review System

How It Actually Works:

Periodic review means counting inventory on a schedule weekly, monthly, whatever works. Essentially, you count everything, compare it to your records, then order what you need.

This works fine for small businesses selling a manageable number of products. However, you’ve got to stay disciplined about counting regularly.

The Good and Bad:

The big advantage? It’s dead simple. You don’t need expensive software just spreadsheets and the willingness to count stuff. Furthermore, it works great if you’re selling 50-100 different items with predictable demand.

The downside? You’re flying blind between counts. For instance, your best seller might run out Tuesday but you won’t know until Friday’s count. Additionally, people make mistakes counting, which throws off your numbers.

Perpetual Inventory System

How This Thing Functions:

Perpetual systems track inventory constantly using technology. Specifically, barcode scanners or RFID tags update your stock control count automatically whenever stuff moves.

Products arrive? Scan them in. Orders ship? System subtracts them instantly. Therefore, you always know exactly what you’ve got without counting everything manually.

Tech You’ll Need:

Setting up perpetual inventory costs money upfront. First, you need inventory software. Second, you need scanners or RFID readers. Third, your products need barcode labels.

Modern fulfillment operations use perpetual systems because accuracy matters enormously when you’re managing inventory for dozens of clients at once.

Why Growing Businesses Love This:

Perpetual systems shine when you’ve got high order volume or tons of products. For example, try counting 500+ different items every week. It’s impossible without a full time person just counting boxes.

Real time visibility changes everything. Consequently, you spot trends faster, catch slow sellers sooner, and reorder before you run out. Customers stay happy. Costs stay low. That’s the dream.

Proven Methods to Improve Stock Control

Implement ABC Analysis for Better Focus

Understanding the ABC Method:

ABC analysis splits your inventory into three groups based on value. Specifically, Class A items are your money makers maybe 20% of products bringing in 80% of revenue. Conversely, Class C items are the opposite lots of cheap stuff that barely moves the needle.

Focus your tightest controls on Class A. They deserve it. Meanwhile, Class C products? Keep it simple.

How to Do This Today:

First, calculate how much revenue each product generates annually. Next, sort them from highest to lowest. Then, classify the top 20% as Class A. After that, the next 30% become Class B. Finally, the bottom 50% are Class C.

Now watch Class A items daily but check Class C weekly. Similarly, keep extra Class A stock but run Class C leaner. Makes sense, right?

Set Strategic Reorder Points

Calculating When to Order:

Reorder points tell you when to place new orders. Here’s the math: (daily sales × supplier lead time) + safety stock.

For example, say you sell 10 units daily and your supplier takes 7 days. That’s 70 units as your reorder point. Plus safety stock for the unexpected stuff.

Safety Stock Math:

Safety stock protects you when demand spikes or suppliers run late. Essentially, how much you need depends on how unpredictable your sales are and how reliable your suppliers are.

Research from Supply Chain Dive shows proper safety stock cuts stockouts by 60-70% without killing you on carrying costs. Generally, 1-2 weeks of demand variation works for most businesses.

Adopt Just In Time Inventory Principles

JIT Basics:

Just In Time means ordering products only when you need them. Specifically, stuff arrives right before you need it for production or sale. Consequently, carrying costs drop. Warehouse space needs shrink.

However, JIT demands reliable suppliers with consistent timing. You can’t wing it with safety stock when you’re running this lean.

Making JIT Work:

Start with products that sell predictably. Next, build strong relationships with suppliers who deliver on time every time. Then slowly order less but more frequently.

For instance, instead of ordering three months of inventory quarterly, order monthly. Or even weekly. Therefore, your cash stays liquid. Inventory turns over faster. Modern fulfillment providers help with JIT by storing inventory near factories, cutting lead times to days instead of weeks.

Leverage Stock Control Software

Features That Actually Matter:

Good inventory software automates the boring stuff. Specifically, look for real time tracking across multiple locations, automatic reorder alerts, demand forecasting from past sales, and connections to your sales channels for automatic updates.

Plus you want reports showing inventory turnover, carrying costs, and stockout frequency. Indeed, data beats guessing every time.

Picking the Right Tools:

Software ranges from basic spreadsheets to enterprise systems costing thousands monthly. Therefore, match complexity to your actual needs. Selling 100 SKUs? Simple tracking software works fine. Conversely, managing 1,000+ SKUs across multiple warehouses? You need the fancy stuff.

Make sure whatever you pick connects smoothly with your existing systems. Otherwise, bad integration creates manual work that defeats the whole point.

Conduct Regular Physical Audits

Why You Still Need to Count:

Even with fancy perpetual systems, you’ve got to count stuff physically. Theft happens. Damage happens. People make mistakes. Additionally, system glitches occur.

Schedule regular cycle counts count 20% of inventory weekly instead of everything quarterly. Consequently, you catch problems faster this way.

Making Audits Work:

First, count high value Class A items more often. Second, investigate big discrepancies to find root causes. Third, fix problems so they don’t keep happening.

Track accuracy as a key metric. Above 95% means you’re doing great. However, below 90%? You’ve got systematic problems needing immediate attention.

Choosing the Right System for Your Business

Small Business Considerations

Processing under 100 orders daily? Periodic review with simple software probably works fine. Nevertheless, even small operations benefit from basic barcode scanning.

Focus on the 20% of products making 80% of revenue. Control those tightly. Meanwhile, manage everything else more loosely.

Scaling to Perpetual Systems

Once you hit 100-200 daily orders, perpetual inventory becomes necessary. Furthermore, growing product catalogs make manual counting impractical.

Plan tech investments as you scale. First, start with basic perpetual tracking. Then, add fancy features like demand forecasting as things get more complex.

Taking Action on Stock Control

Getting your stock control system right transforms inventory from a constant headache into a competitive edge. Furthermore, the right approach keeps customers happy while your cash flow stays healthy.

Start by honestly assessing where you are now. What’s your biggest problem running out of stuff, too much inventory sitting around, or just not knowing what you’ve got? Therefore, pick systems and methods that fix those specific issues.

Most growing businesses gradually move from periodic to perpetual systems. However, start with ABC analysis though it needs minimal tech investment but delivers big focus improvements immediately.

Perfect inventory control evolves over time through consistent improvement. First, measure key metrics. Next, find weak spots. Finally, fix problems systematically. Your stock control gets better as your business grows.

Frequently Asked Questions

What is a stock control system?

A stock control system is how businesses track and manage inventory levels. It monitors current stock, alerts when reordering is needed, and helps balance meeting customer demand against minimizing excess inventory costs.

What's the difference between periodic and perpetual inventory systems?

Periodic systems involve manual stock counts on schedules like weekly or monthly. Perpetual systems track inventory continuously in real time using barcode scanners. Perpetual gives more accurate information but costs more to set up than periodic approaches.

How do I calculate reorder points?

Use this formula: (average daily sales × supplier lead time in days) + safety stock. If you sell 15 units daily and suppliers take 10 days to deliver, your reorder point is 150 units plus whatever safety stock you need for demand spikes.

What is ABC analysis in inventory management?

ABC analysis splits inventory into three classes by value. Class A items (20% of products) generate 80% of revenue and need tight control. Class B items (30%) contribute moderate revenue with moderate control. Class C items (50%) generate minimal revenue needing simpler management.

How often should I conduct physical inventory audits?

Audit frequency depends on value and turnover. High value items might need monthly or weekly verification. Low value items can be quarterly. Cycle counting where you count different sections on rotating schedules beats infrequent full counts.

What software do I need for stock control?

Needs depend on size and complexity. Under 100 SKUs might just need simple tracking software. Larger operations require dedicated systems with barcode scanning, multi location tracking, demand forecasting, and sales channel integration.