Customer reviews reveal everything. “Best store ever super fast delivery!” versus “Never received my order terrible!” The difference comes down to one thing: your order fulfillment system.

Poor fulfillment destroys businesses fast. Great fulfillment creates loyal customers who buy repeatedly. Here are six practical ways to fix common fulfillment problems and keep customers happy.

Promise Only What You Can Actually Deliver

Many businesses make a critical mistake they promise more than they can deliver. You might advertise 2 day shipping when your actual average is 5 days. This creates disappointed customers every single time.

Be honest about your current capabilities. Monitor your real performance over the past 30 days. When do orders actually ship? How long does delivery really take? What percentage gets damaged or lost?

Under promising and over delivering beats the opposite every time. Promise 5 day delivery and arrive in 3 days? Customers feel delighted. Promise 2 days but take 5? They feel cheated and angry.

According to Shopify’s fulfillment research, customers value honesty over speed. They prefer knowing the real timeline upfront rather than being surprised by delays later.

Set expectations based on reality, not wishful thinking. Your order fulfillment system performs better when you stop over promising and start delivering consistently on realistic commitments.

Monitor Demand Patterns for Efficient Planning

Your order volume changes constantly. Black Friday looks nothing like a random Tuesday in February. Understanding these patterns prevents major headaches.

Track when orders spike throughout the year. Which months see the highest volume? What days of the week get the most orders? When do specific products sell fastest?

This data helps you staff appropriately and manage resources. Running at full capacity year round exhausts your team and wastes money during slow periods. Being understaffed during peaks creates backlogs and delays that hurt customer satisfaction.

Build a simple demand forecast using historical data. Watch for big events that increase orders like holidays, sales, and product launches. These create predictable patterns you can prepare for.

Modern fulfillment service providers use sophisticated demand forecasting to adjust resources automatically. Even if you handle fulfillment yourself, basic pattern tracking makes a huge difference.

Match your capacity to actual demand. Your system runs smoothest when you scale up for busy periods and scale back during slower times. This approach saves money while maintaining service quality.

Choose Delivery Carriers Based on Performance

Big name carriers sound impressive, but name recognition doesn’t guarantee good service. Some famous carriers have terrible track records for certain routes or package types.

Research carriers based on your specific needs. Where do most customers live? What package sizes do you typically ship? Do you need international capabilities? These factors determine which carrier works best for your business.

Compare rates carefully, but don’t make price your only consideration. A carrier charging 20% less but damaging 10% of packages costs more in replacements and lost customers.According to Supply Chain Dive, reliable delivery matters more to customers than low prices.

Read reviews from actual businesses using these carriers. Ask other e-commerce owners about their experiences. Join online communities where sellers discuss carrier performance honestly rather than repeating marketing claims.

Test new carriers with smaller volumes before committing to contracts. Send 50-100 orders through them and track results carefully. How many arrive on time? How many get damaged? How responsive is customer service when problems occur?

Replace Lost or Damaged Items Immediately

Products get lost during shipping. Boxes arrive damaged. These problems happen in every order fulfillment system regardless of how careful you are.

Your response determines whether customers give you another chance or leave bad reviews. Replace damaged or lost items immediately without creating obstacles for customers.

Yes, replacements cost money there’s no avoiding that. But losing customers costs far more. One negative experience shared on social media reaches hundreds of potential customers. Losing one customer forever costs way more than a few replacements.

Make your replacement policy simple and customer friendly. When customers report problems, ship replacements immediately. Don’t require multiple photos, formal complaints, or waiting for lengthy carrier investigations. Handle internal processes after solving the customer’s immediate problem.

Monitor replacement patterns to identify root causes. If one carrier consistently damages items, switch carriers. If certain products always arrive broken, improve packaging. If specific delivery routes see high loss rates, find alternative shipping methods.

These replacements protect your reputation short term. Analyzing patterns and fixing underlying issues prevents problems long term. This dual approach keeps customers happy while reducing costs over time.

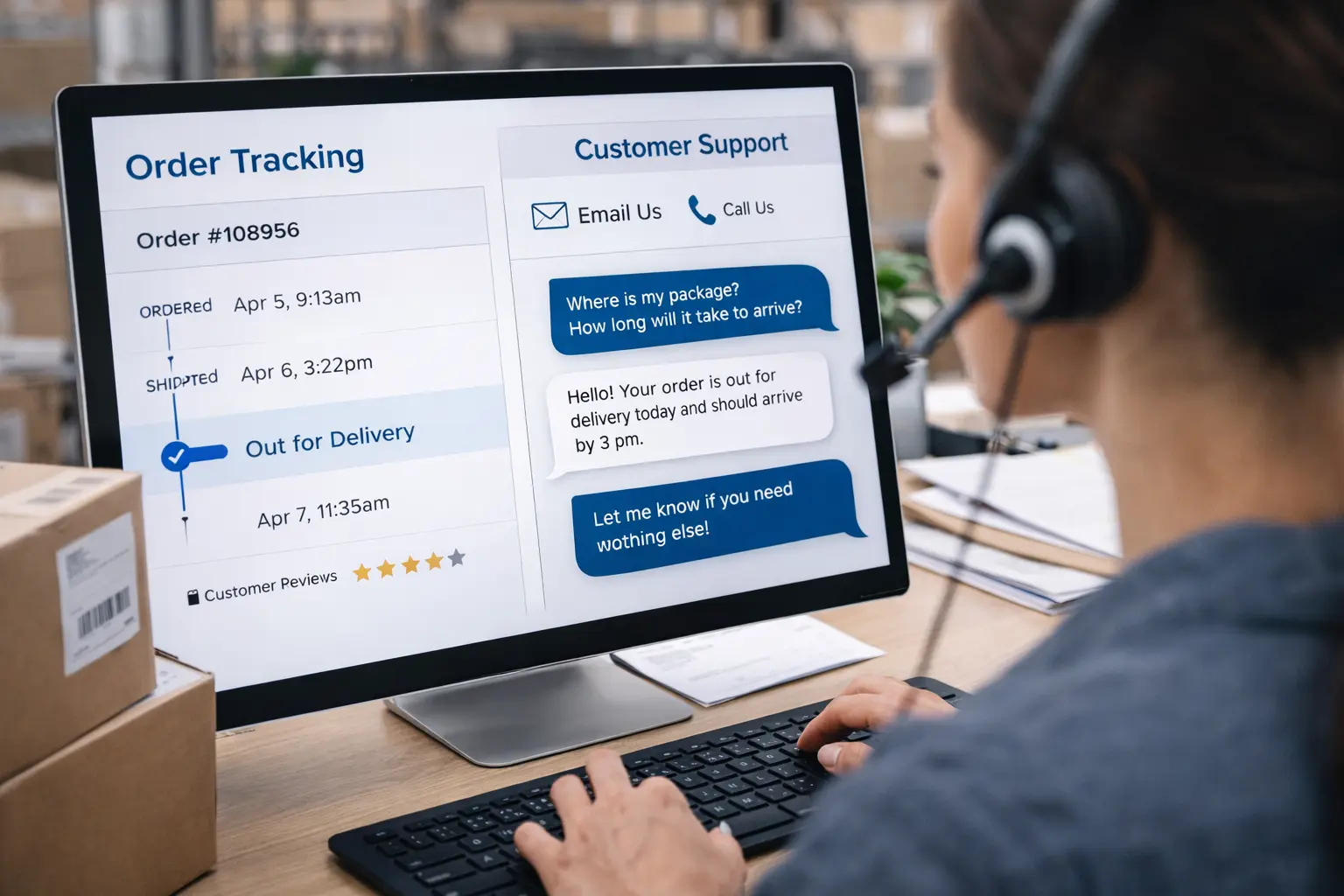

Build Responsive Customer Service Capabilities

Contact information that leads nowhere destroys customer trust instantly. Automated responses without real human follow up frustrate people. Support tickets taking 48+ hours to answer lose sales and damage reputation.

Customers need to reach you when questions arise about orders. Common questions include “Where’s my package?” and “Can I change my delivery address?” and “My order arrived damaged.” These need answers within hours, not days.

Responsive customer service accomplishes two critical goals. First, it solves problems before they explode into angry social media posts. Second, it builds relationships converting one time buyers into repeat customers.

Train support teams specifically on fulfillment issues. They should track orders, explain delays honestly, handle replacements fast, and report urgent problems. Generic “we’ll look into it” responses don’t satisfy customers.

Offer multiple contact methods. Some customers prefer email. Others want phone support. Live chat during business hours provides quick answers. Modern fulfillment operations integrate customer service directly with order tracking systems, giving support teams real time visibility into every order’s status.

A business customers can’t contact looks suspicious or unprofessional. A business responding quickly and solving problems builds trust and loyalty.

Review Performance Data Regularly

Your order fulfillment system needs regular checkups just like your physical health. Monthly performance reviews catch small problems before they become major disasters.

Review key metrics consistently every month. How many orders shipped on time? What’s your average processing time from order receipt to shipment? What percentage of orders arrived damaged? How many got lost completely? What’s your customer complaint rate?

Compare current performance to previous months. Are you improving or declining? Seasonal patterns matter November should look busier than February but overall trends matter more than individual data points.

Look beyond raw numbers at actual customer feedback. Read reviews about delivery experiences. What specific complaints appear repeatedly? What do satisfied customers praise about your fulfillment?

Identify your biggest problem area each month and focus on fixing it. Maybe shipping labels print incorrectly sometimes. Maybe one warehouse location consistently runs slower than others. Maybe weekend orders don’t ship until Tuesday morning.

Fix one major issue at a time rather than attempting to overhaul everything simultaneously. Small, consistent improvements compound into significant performance gains over several months.

Schedule these reviews on your calendar monthly. Make them non negotiable appointments even during busy periods. The busiest times often hide the biggest operational problems that need addressing.

Conclusion

Your order fulfillment system directly determines whether customers buy from you again or leave negative reviews. Fast, accurate delivery builds loyalty and positive word of mouth. Slow, error prone fulfillment destroys both quickly.

Start with honest assessment of current capabilities. Promise only what you can consistently deliver. Track demand patterns so you’re prepared for volume spikes. Choose carriers based on actual performance data rather than just brand names or prices.

Replace problems immediately to maintain customer trust. Build real customer service capabilities that respond quickly. Review performance data regularly and fix issues systematically.

Small improvements compound significantly over time. A business improving shipping speed by just 1% monthly becomes dramatically more competitive within a year. A business reducing errors by a few percentage points quarterly builds a strong reputation for reliability.

Your fulfillment either accelerates growth or creates obstacles preventing it. The choice depends on how seriously you take these fundamental operational principles.

Frequently Asked Questions

What is an order fulfillment system?

An order fulfillment system manages the entire process of getting products to customers. It covers inventory, order processing, warehouse packing, carrier selection, shipping, and tracking. The best systems run smoothly with minimal errors.

How can I improve order fulfillment speed?

Make fulfillment faster by automating orders and organizing your warehouse better. Process similar orders together and pick faster carriers. The biggest improvement? Remove manual steps where orders just sit waiting.

What causes most order fulfillment errors?

Most errors come from manual typing. Staff make mistakes when entering addresses, selecting products, or typing tracking numbers. Automation that links your store to your warehouse cuts out these errors completely.

How do I choose the right delivery carrier?

Try different carriers with actual orders first. Watch delivery times, damage rates, and how quickly they help when issues pop up. Pick the one that’s reliable for your specific needs, not just the cheapest or most famous.

Should I handle fulfillment myself or outsource it?

Handle it yourself if you ship fewer than 100 orders per day, have special products, or need complete control. Outsource when you can’t keep up, want to sell internationally, or it’s cheaper to let professionals handle it.

How often should I review fulfillment performance?

Review performance at least monthly. Watch order volume, how fast you process and ship, damage rates, and complaints. Check more frequently during holidays to spot issues before they get big.