Most e-commerce entrepreneurs ignore warehousing systems probably because many of them aren’t connected enough with their warehouses. After all, that’s one of the reasons they hire fulfillment centers – so these centers will do the warehousing work for them.

Of course, we will do your warehousing work for you, but it’s good you know what makes a great warehousing system and what isn’t.

Simply put, your warehouse have a huge impact on your business. This is the first line of operations before all the packaging and shipping comes from; if anything, this is just second to manufacturing. It’s one thing to manufacture your goods, but most of the time, they will stay in a warehouse until asked for delivery. It’s best, then, you keep an eye on your warehousing system – whether you plan to own your own one someday or remain to the services of a fulfillment center.

Without further ado, here are the 5 basic factors to look in for a fulfillment center’s warehousing system or service.

1) Warehouse Space and Design

Your fulfillment center’s warehouse must be large. There are two reasons for that:

a. Warehouse capacity – you’re not the only one your fulfillment center is taking care of, so expect a tons of products coming in from different stores. And if you have a tons of products yourself, it’s in your best interest that your fulfillment center own a large warehouse – at least, spacious enough to fit the products in.

b. Handling and Management – If the warehouse is small, your workers might cramp around, making them less efficient, slow, and even break packages or send them to wrong carriers. Having a large space will mostly eliminate these problems; it’s really just a matter of space.

2) Experienced and Productive Workers

Simply put, you must hire as much as possible the best workers; that is already a given.

Your workers should know the basics of warehouse management – how to handle packages, where to stock them, how to transfer them, how to take care of them, and how to send them to proper carriers (to avoid wrong deliveries).

But there’s another side to this coin: incentives.

The warehouse management must offer proper incentives to their workers; otherwise, the workers won’t work to their full potential.

We will skip most of human resource management here, but one thing that must be noted is that many management have poor incentives to their workers. They seem to think that their workers will always be delighted to work despite delayed payments, little performance incentives, and sometimes even verbal abuse from their superiors.

Management and workers should work together well if they are to maximize the output of the business.

This is not to say that management is always wrong; it’s right – and necessary – to fire lazy workers.

But if you have the best people around, treat them well, and they mostly respond by treating you well, too.

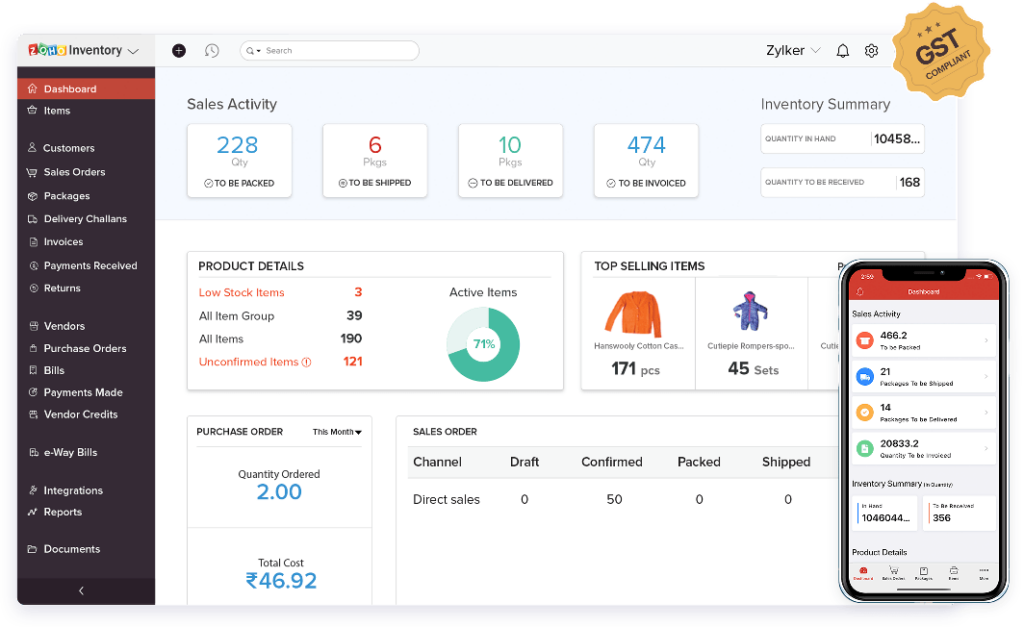

3) Using the Latest Information Technology

Here at Fulfillmen, we have adopted several automated systems to ensure the processes for each workstation is quick and smooth.

We are now in the ever-changing fast pace world of business, so speed is very, very important here.

Get all the tracking software, people management software, and other software and systems you can use for your warehousing system.

You don’t have to get all of the software and systems, though; just what’s necessary is enough.

The key is to make your systems faster and more efficient.

4) Adopt Real-Time Tracking Systems

One way to automate your system and enhance your warehouse’s efficiency is by adopting a real-time tracking system.

This tracking system should let you know where each package are located to where, and, if possible, let you know their physical condition – if they are in good condition, slightly damaged or totally damaged. And let’s hope you don’t want to see the word “damaged”.

Having a real-time tracking system will help you and your workers in processing products and delivery. It will make all carriages faster because you have a wide blueprint on where the products will come and go.

5) Carrying Out Regular Maintenance

Lastly, a factor you should consider is regular maintenance. Like anything else, warehouses – and your warehousing system – suffer wear-and-tear over time.

If this is left without treatment, this can do some serious damage to the business.

If not you, at least your fulfillment center should do that for their warehouse. Some things to consider are:

- Physical condition of the warehouse

- Physical condition of the warehouse’s tools – the shelves, forklifts, computers, ventilators, etc.

- Worker performance over a selected period of time.

- Automated systems and software – check if they are still up-to-date, and if they deliver the result you look for.

Conclusion

Don’t compromise your warehousing solutions; it will make or break your business’ long-term operations.

Here at Fulfillmen, we ensure our warehousing solutions work to the best of its quality – and always looking for ways to improve.

If you have any questions, you can always reach us through our customer service representative.